by Mary | Nov 23, 2015 | Construction, Design News, Interior Design, Workplace Design

While Michigan has been “rich” with energy for several generations, recently r.o.i. Design has learned more about how communities are powered.

Through the invitation of Richard Skendzel of Architectural Technology in Traverse City, MI we met Wolverine Power Cooperative in Cadillac, MI and were engaged as interior designers for their new 40,000 SF corporate office. The new facility is being built adjacent to their existing offices on beautiful wooded acreage.

Planning for the housing of this growing team of engineers, planners, project managers and administrators has been the work of Eric Baker, CEO, Dawn Coon, Executive Assistant, and Tim Martin, Manager of Energy Operations.

The facility has been designed to nestle in the landscape, celebrating the Northern Michigan environs. The building sits low in the horizon but the interior spaces feel sky-high.

Some of our favorite features so far are the ceiling clouds, radius walls and specialty lighting. Project completion Winter 2016.

Rendering of Proposed Lobby

Bulkhead at Reception

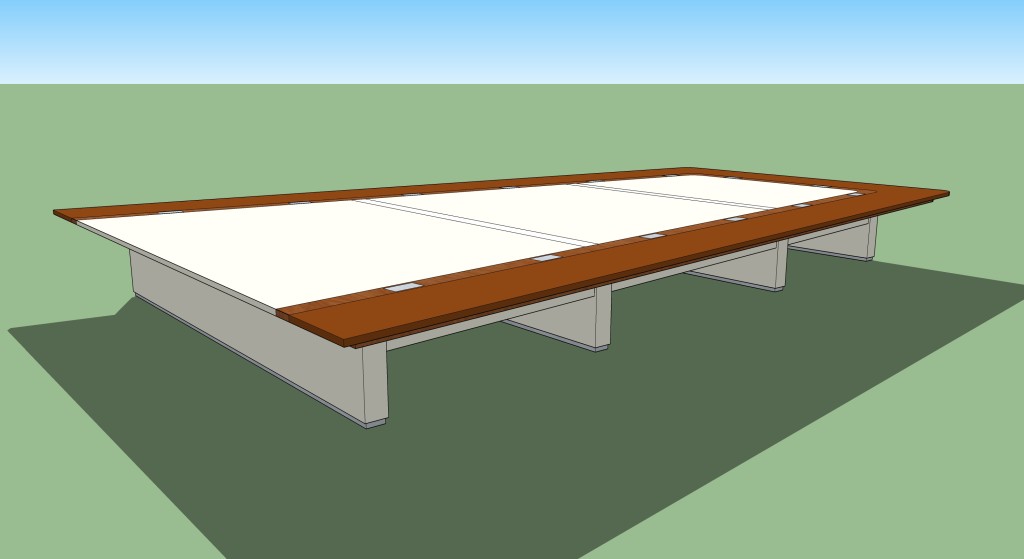

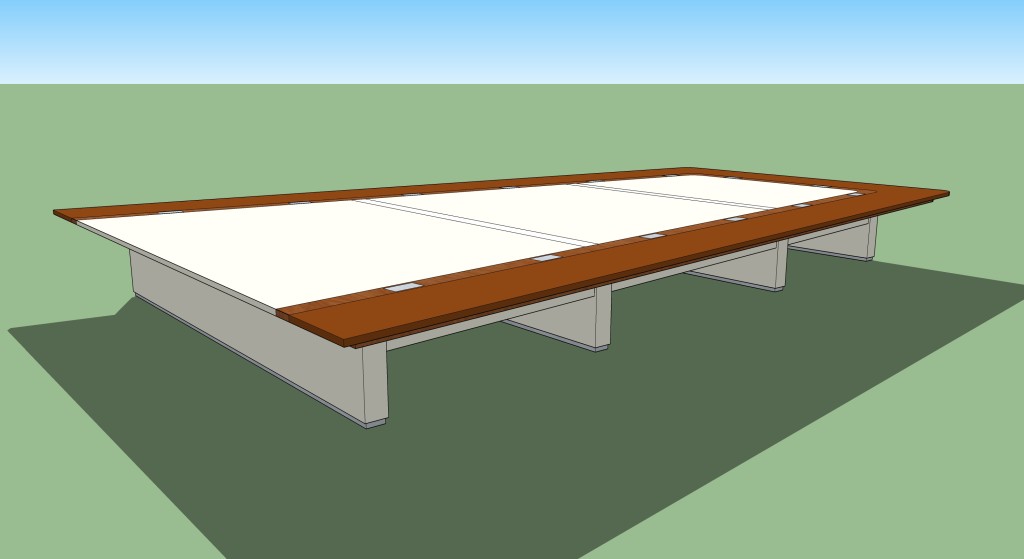

Building of Ceiling Cloud in Board room

by Mary | Nov 23, 2015 | Construction, Design News, Interior Design, Meeting and Conference

Not that long ago, we showed up at the City of Grand Rapids building department offices and we were greeted by “What old building are you working on now?” How did we get that recognition?

Maybe its because we renovated a 110 year furniture manufacturing building for our own offices, or maybe it’s because we were the designers of the first loft style work environment on the West Side of Grand Rapids more than 20 years ago, “The Grand Rapids Furniture Campus”.

But more recently, the recognition may be for our work with JGR Real Estate and another 100 year old manufacturing company.

JGR Real Estate Offices

Julie Grevengoed, Owner and Broker of JGR Real Estate purchased an vacant store front on the corner of Bridge and Seward in the West Side of Grand Rapids. JGR had to renovate the entire interior and improve the exterior façade to meet her business needs as well as the requirements of the City of Grand Rapids. r.o.i. Design created the space plan, lighting plan and worked with Wolverine Building, Mike Kelly, to help turn this once pawn shop into a contemporary and inviting space.

Currently we are working on another “antique” owned by an international company who is converting an old manufacturing space into a meeting and conference area for their North American operations. Their teams will gather here for training and innovative collaboration on designing new products. Project is scheduled for January 2016 completion.

It is also possible we are known for the design and re-purposing of old spaces because we have been in the business of delivering a return on investment to our design customers for more than 20 years.

100 Year Old Manufacturing Space Before Renovation

Renovation in Process

Renovation in Process

by Mary | Oct 13, 2015 | Hospitality Design, Interior Design, Procurement and Purchasing, Project Management

With the increase of new hotel and resort projects, as well as robust remodeling, owners and construction project managers are re-examining how they fulfill the millwork and casegood category of their building projects.

r.o.i. Design describes millwork as casegoods that are fixed to the architecture. Casegoods (typically described in the furniture category) and millwork are amortized differently on the balance sheet and quite often supplied by different sources. This area of procurement is a challenge but also an opportunity.

Aside: The debate about buying US or non-US continues, but the more foreign manufacturers merge their offering with state side distribution, the point of manufacturing is becoming less of a political, economic issue. We all need each other, globally to make our businesses work, within reason. Logistics and the chain of ownership continues to be the defining component to value and control.

r.o.i. Design can contribute to this dialogue with these observations:

- Understanding: When the customer understands that the total cost of a product includes, freight, handling, staging and delivery-the criteria may change. The age old mantra, “you can have 2 of the 3 – 1. design, 2. price or 3. schedule” still holds true.

- Flexibility: And when the project team is willing to look at qualified suppliers outside their list of typical vendors, value can be realized.

- Cost Analysis: Overseas products may show up with a reduced unit price, but the cost and risk to get those products to the site, as designed and on time is not always as manageable. We see this situation being improved incrementally and by situation, but as of October 2015, we don’t make price or lead time promises on overseas product without considerable confirmation and agreement.

- New Materials and Technology: While process and manufacturing styles for US manufacturers are consistent, their emerging ability to use new materials and technology are offering a value that competes with the “all in costs” of overseas manufactures.

- Design-Assist: When project budgeting can take advantage of qualified suppliers, early in the process, value is realized. Sharing the designing of products with the makers of the products only makes sense to our customers.

Textured Melamine

New Materials

In the last few years, r.o.i. Design has specified “new materials” with great success.

- Textured melamine panel products offer a huge advantage for larger projects.

- The big names in laminate (Formica, Wilsonart, Pionite and Nevamar) have done there homework and laminate, an affordable option, is becoming a more viable option to wood or stone in today’s designs.

- And the combined use of solid surface veneer with laminates has created options for look and feel not available even a year ago.

- Upholstered casegoods are a viable option. Technology and design has created a category of fabric that defies wear, responds to robust cleaning and is easily replaceable. Fabrics are merging with hard surface options.

r.o.i. Design has it roots in manufacturing for hospitality and while we only have a sample shop today, our interest, relationships and experience in casegoods and millwork continue to bring value to our customers.

We negotiate with our customers and their contractors to determine how we best can bring value to their millwork and casegood procurement.

by Mary | Oct 13, 2015 | Hospitality Design, Meeting and Conference

Businesses and associations are starting to promote business gatherings again. The economic hardship of the last 5-8 years drastically impacted that business for properties; now groups are reconsidering the away-training , coincidentally, there are some requests being made of facility design and service from those groups.

Properties have analyzed how many unique guests visited their property in a year, and they know it is possible that more people experience a hotel or resort for a meeting than those whose who come for more than 2 day stay. The meeting and conference business fuels the social business and vise-versa. Properties are more interested than ever to meet new people, offer them hospitality or a day, in hopes they will return for more.

r.o.i. Design has been responding to properties changing needs for meeting and conference, and we share here the trends we see.

In general, the trend is toward “conversation” and “community” supported by technology.

Properties group sales staff are working with a wide variety of “hosts”, not just the millennial.

The decision maker varies in age, experience, role and most importantly by requests. There is not one customer to please. Properties are becoming more and more agile in their response to the meeting and conference business. That means flexibility in furnishings, meals, technology and overall schedule.

Joshua Prager at TED@NewYork talent search. June 7, 2012. New York, NY. Photo: Ryan Lash

Seating options are no longer limited to banquet, training and theater style layouts.

The incoming group is looking for a wider variety of seating options, and not just for the meeting but for break out and meal arrangements as well. r.o.i. Design has studied this and found a correlation between this expectation and the customers current experience of other environments, including but not limited to, coffee lounges, retail spaces, a recent local “Ted Talk”, church assemblies, university classrooms (virtual and brick) and their own homes. The challenge is to make one group of inventoried furniture morph into a variety of experiences. Requests for accent pillows, more side tables or even lamps have started to show up.

Technology not only means that the participant has to get online.

The presenter needs to have clear access to the internet and an easy way to show their presentation. Offering a plug and play that is effortless for the presenter and allows participants to use their lap tops to also dial into the presentation is going to be the norm.

Lighting and lighting controls need to be controlled by the guest.

If a group is looking at their lap tops to get a better look at the shared presentation they may need a dimmer setting of overhead lights, or if the audience has to be woken up after lunch the present may want to increase light levels, or if the ambient light is changing from daylight to evening, the group needs to have control.

Break Out Spaces with Options

Gluten free, vegetarian, Indian vegetarian, vegan…

The percentage of special meal requests is increasing. The ill fated salad bar is dead but properties are figuring out how to create a manageable “buffet” that each guest can customize without the kitchen having to go through cart wheels to feed the diverse palette. The most innovative are including the guest in their food preparation and providing a lot of options for seating within a proximity of the whole.

Properties are discovering that some of their spaces that may not have been previously considered as viable “meeting and conference” assets to be very appealing to customers.

r.o.i. Design acknowledges that the most successful one day hospitality experiences are the result of an innovative staff, an engaged host, an informed speaker and a facility inventoried with all the items needed to encourage a unique experience.

by Mary | Oct 7, 2015 | Construction, Design News, Interior Design, Project Management

Where do you learn about drones, BIM, Design-Assist? Turns out at the Fall COAA Workshop in Novi, Michigan.

Over 75 construction and design professionals gathered for a day of learning and networking in September 2015. Mary Witte, from r.o.i. Design attended.

The second session of the day was a presentation by three members of COAA, an owner, an architect and an contractor. This was a candid discussion of the process of building the team that determines the design, the cost and the timeline for buildings.

For r.o.i. Design, their comments about pre-qualifying team members through a RFQ (Request for Qualification Process) made a lot of sense and we understand how this step potentially saves the owner/project a considerable amount in fees. The presenters suggested that a large RFP (Request for Proposal) process could involve over 10,000 hours in professional time and still doesn’t guarantee best outcomes. They asked they question, “What can we take from the interviewing and bidding process to add value to the job?” Owners are living with a project long after the architect and contractor are gone, the decision who is on the team has a legacy implication. Start with clear understanding of what is important to the owner and let that drive the process of assembling the best team for the job. (Presenters: Leisa Williams-Swedberg, construction Administrator, Michigan State University, Nick Salowich, Principal, Science & Technology Studio Leader, Smith GroupJJR, Robert LaLonde, LLED AP, Vice President Clark Construction).

r.o.i. Design Pre-Design Rendering

Target Value Design (IPD-Integrated Product Delivery) was the topic of the third session.

This group of presenters, again from different disciplines, highlighted a process that, in r.o.i. Design’s view, was advocating for integration of the builders & makers into the budget and design process much earlier than the traditional model. (That model being: Concept, Design, Develop Design, Schematic Design, Construction Documentation 75%, 90% etc. ). This group asks the question, why does there need to be value engineering, why not value designing-real time analysis that is meaningful.

Whether designing a building or a table, consider bringing in the makers early in the process. Custom conference table designed by r.o.i. Design.

This discussion raised our awareness that designers have an opportunity to serve our clients by promoting a new process: Create 3-D illustrations to describe design intent to such detail that all related trades can begin to work on documents that build the design in a collaborative and integrated way. This also raised the concern on how designers would be compensated for their ideas, which began a discussion on the true nature of team. (Presenters: Anthony Bango, Vie President Project Planning, The Christman Company; Matt Cramer, President, De Cramer Inc; Kevin Kershbaum, HGA Architects)

r.o.i. Design understands that designers bring the greatest value to owners in two ways- creativity and management. Clearly describe the concept that meets the expectations and needs of the customer, and then manage the process. That doesn’t mean making every decision, drawing every schematic or trying to be the expert.

The final presentation felt like a continuation of the previous discussion, but with more “math”.

Design-Assist is a method of design-to construction that also engages contractors early in the process of planning. The presenters introduced the idea of all participants in a project to consider themselves “partners”. That would mean share the savings, share the profits, and be transparent with the opportunity for improvements. Any conflict over who owns ideas and solutions has no room in a design-assist process. This discussion looked at the opportunity to avoid “waste”: duplication of services, postponing decisions or making half decisions on half the information. This discussion gave us insight into an opportunity to develop respect and trust among team members. We are all conditioned and comfortable with our process, change is hard, but the future of construction has to be LEAN. (Presenters: Victor Sanvido, Senior Vice President, Southland Industries; George Karidis, PE, LEED AP BC+C, vice President, Corprate Engineer for Scince & Technology, SmithGroup JJR)

GVSU Marketplace Mary Jane Caster, Mary Witte, (Designers) and Carol Cool (GVSU Project Manager)

From Mary Witte: Through the day, I reflected on the r.o.i. Design “Budget, Brand and Beauty” story and was excited that our choice of practice is on track with the trends in our industry. Start with the owners values and interpretation of quality, develop a team, share all the information with the team, create process and structures that are inclusive and helpful, trust your team and ask them to trust you.

**

r.o.i. Design has been working with Grand Valley State University since 2009 and through that work we discovered COAA. We have been impressed with the people and the quality of the information presented by and to the membership. It is a national organization with State Chapters. The Michigan Chapter presents two workshops a year, promotes their national training programs and encourages its members to attend the National Convention. We are proud members of COAA. www.coaa.org

r.o.i. Design has been working with Grand Valley State University since 2009 and through that work we discovered COAA. We have been impressed with the people and the quality of the information presented by and to the membership. It is a national organization with State Chapters. The Michigan Chapter presents two workshops a year, promotes their national training programs and encourages its members to attend the National Convention. We are proud members of COAA. www.coaa.org