Where do you learn about drones, BIM, Design-Assist? Turns out at the Fall COAA Workshop in Novi, Michigan.

Over 75 construction and design professionals gathered for a day of learning and networking in September 2015. Mary Witte, from r.o.i. Design attended.

The second session of the day was a presentation by three members of COAA, an owner, an architect and an contractor. This was a candid discussion of the process of building the team that determines the design, the cost and the timeline for buildings.

For r.o.i. Design, their comments about pre-qualifying team members through a RFQ (Request for Qualification Process) made a lot of sense and we understand how this step potentially saves the owner/project a considerable amount in fees. The presenters suggested that a large RFP (Request for Proposal) process could involve over 10,000 hours in professional time and still doesn’t guarantee best outcomes. They asked they question, “What can we take from the interviewing and bidding process to add value to the job?” Owners are living with a project long after the architect and contractor are gone, the decision who is on the team has a legacy implication. Start with clear understanding of what is important to the owner and let that drive the process of assembling the best team for the job. (Presenters: Leisa Williams-Swedberg, construction Administrator, Michigan State University, Nick Salowich, Principal, Science & Technology Studio Leader, Smith GroupJJR, Robert LaLonde, LLED AP, Vice President Clark Construction).

r.o.i. Design Pre-Design Rendering

Target Value Design (IPD-Integrated Product Delivery) was the topic of the third session.

This group of presenters, again from different disciplines, highlighted a process that, in r.o.i. Design’s view, was advocating for integration of the builders & makers into the budget and design process much earlier than the traditional model. (That model being: Concept, Design, Develop Design, Schematic Design, Construction Documentation 75%, 90% etc. ). This group asks the question, why does there need to be value engineering, why not value designing-real time analysis that is meaningful.

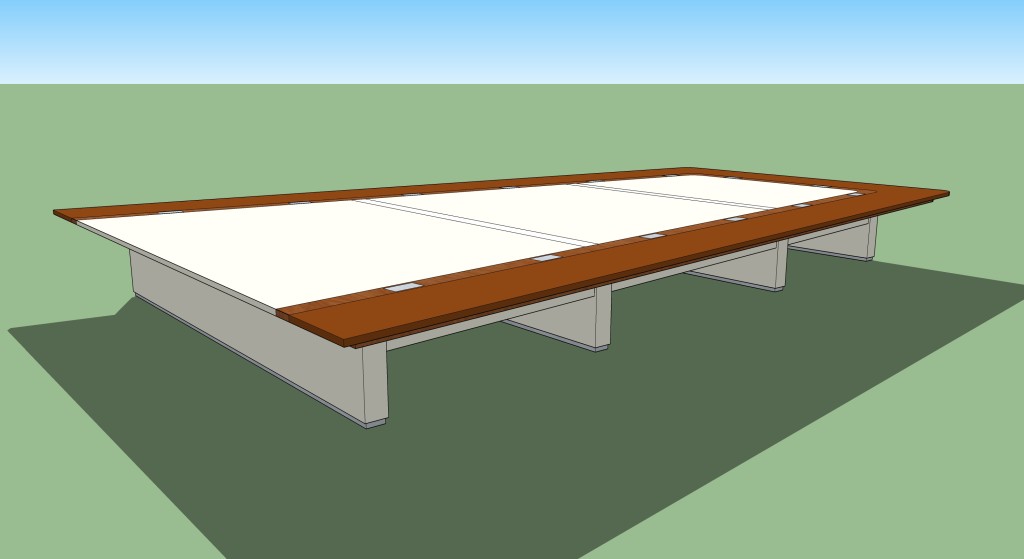

Whether designing a building or a table, consider bringing in the makers early in the process. Custom conference table designed by r.o.i. Design.

This discussion raised our awareness that designers have an opportunity to serve our clients by promoting a new process: Create 3-D illustrations to describe design intent to such detail that all related trades can begin to work on documents that build the design in a collaborative and integrated way. This also raised the concern on how designers would be compensated for their ideas, which began a discussion on the true nature of team. (Presenters: Anthony Bango, Vie President Project Planning, The Christman Company; Matt Cramer, President, De Cramer Inc; Kevin Kershbaum, HGA Architects)

r.o.i. Design understands that designers bring the greatest value to owners in two ways- creativity and management. Clearly describe the concept that meets the expectations and needs of the customer, and then manage the process. That doesn’t mean making every decision, drawing every schematic or trying to be the expert.

The final presentation felt like a continuation of the previous discussion, but with more “math”.

Design-Assist is a method of design-to construction that also engages contractors early in the process of planning. The presenters introduced the idea of all participants in a project to consider themselves “partners”. That would mean share the savings, share the profits, and be transparent with the opportunity for improvements. Any conflict over who owns ideas and solutions has no room in a design-assist process. This discussion looked at the opportunity to avoid “waste”: duplication of services, postponing decisions or making half decisions on half the information. This discussion gave us insight into an opportunity to develop respect and trust among team members. We are all conditioned and comfortable with our process, change is hard, but the future of construction has to be LEAN. (Presenters: Victor Sanvido, Senior Vice President, Southland Industries; George Karidis, PE, LEED AP BC+C, vice President, Corprate Engineer for Scince & Technology, SmithGroup JJR)

GVSU Marketplace Mary Jane Caster, Mary Witte, (Designers) and Carol Cool (GVSU Project Manager)

From Mary Witte: Through the day, I reflected on the r.o.i. Design “Budget, Brand and Beauty” story and was excited that our choice of practice is on track with the trends in our industry. Start with the owners values and interpretation of quality, develop a team, share all the information with the team, create process and structures that are inclusive and helpful, trust your team and ask them to trust you.

**

![]() r.o.i. Design has been working with Grand Valley State University since 2009 and through that work we discovered COAA. We have been impressed with the people and the quality of the information presented by and to the membership. It is a national organization with State Chapters. The Michigan Chapter presents two workshops a year, promotes their national training programs and encourages its members to attend the National Convention. We are proud members of COAA. www.coaa.org

r.o.i. Design has been working with Grand Valley State University since 2009 and through that work we discovered COAA. We have been impressed with the people and the quality of the information presented by and to the membership. It is a national organization with State Chapters. The Michigan Chapter presents two workshops a year, promotes their national training programs and encourages its members to attend the National Convention. We are proud members of COAA. www.coaa.org