“Awwh… do we have to talk about the budget?”

“Awwh… do we have to talk about the budget?”

Probably the most difficult thing for a recently graduated design student entering the workforce is the perceived limitation that a budget has on their design. And it isn’t always just the young professional, sometimes the customer is deflated that initial planning has to start with a discussion on budgets. “We don’t want to limit your creativity” is the cry, “Can’t we just let you design and then price it all out?”

The answer is “of course”, but we caution that redesign also creates more design fees and in some cases an extended schedule. And always some disappointment.

So what is the r.o.i. Design solution to managing budget and creative expectations? We focus on the customer:

- Overall, we are open and flexible about product selections, knowing that the budget isn’t completely known on start and change will be needed.

- No design should be dependent on any one element; everything is replaceable.

- We also remind ourselves continually that the perception of quality is a standard the customer sets, not the designer.

- We are happy when our customer is happy.

Then we practice at least six budget disciplines when designing. They are:

1. Qualifying Expectation at the Start:

While developing the concept, we inquire about budget in a general way. The customer isn’t going to be able to give the design team a specific budget but how they describe their hope for final costs is very telling. “Well, we are hoping we don’t have to go to the bank to finance this” or “It is important that the design of our space reflects the quality of our product” or “We need to spend “x” amount before the end of our fiscal year.” All communicate something about the budget. If there is a contractor already on the job, they probably have discussed a budget and they are likely able to give guidelines. This research may not result into a developed budget of any kind, but we can tell what kinds of finishes would be “outside” the budget just with a little information.

2. Budget Before Design:

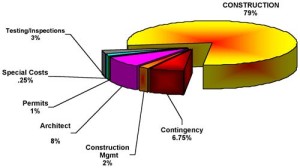

Typically we like to outline the concept and get the customer and contractor around the table to discuss what could be the design. We assemble photos, sketches, materials – all that we think may be appropriate for the project. We may have hand sketches and layouts that show solutions to key space planning or lighting issues. The concept review meeting results in a budget. Our template for this budget at the design stage has the following header. “This budget is not a proposal for resale of goods or services and is only intended to broadly view project budgets as a tool to make decisions regarding the design.” We are not magicians or fortune tellers, we can’t predict a budget exactly but by developing a budget at this stage does highlight where there are unexpected costs resulting in discussion about elements before design starts in detail.

3. Cross Checking Expectations with Contractors and Builders:

3. Cross Checking Expectations with Contractors and Builders:

No two jobs are a like. Sometimes r.o.i. design is hired by the contractor, sometimes the customer hires us and then solicits bids based on our deliverable, and other times contractors work along with us side by side to develop design and budget. Which ever way, it is important to have a shared understanding with the contractor on what the finish material unit costs need to be as part of the overall cost. As trade professionals, often we are exposed to price lists of products that are not at a “retail” price. Wholesale pricing cannot be used in budgets. The cost to the customer is based on the channel of distribution and related margins added to costs to pay for all layers of distribution, freight and handling expense to the site. There is also the issue of take-off’s and quantity needed. Recently, we specified a mid grade contract wallcovering for a medium sized office project. Budget reviews based on concept thought the $16 a yard was an affordable price for the wallcovering. It wasn’t until the installer estimated that over 100 yards was needed because of pattern repeats, and the related labor cost escalated because of increased yardage, the “in budget” material was no longer “in budget”. The discovery was made before the finish specifications were written and a re-selection was made as well as a reduction in wallcovering.

4. Reviewing Submittals:

Sometimes installers will engage us in a conversation regarding a product spec prior to them purchasing and installing. It is always better to have someone complain to us about cost verses going to the customer. And sometimes there are mis-interpretations of specifications that result in an unexpected price, and preview allows for errors to be corrected before items are purchased and installed.

5. Value Engineering and Substitutions:

5. Value Engineering and Substitutions:

On most jobs, there are typically a few items that the customer “really” likes, but we know are potentially budget busters. For example:

This year customers have come to us with requests for translucent walls made popular by 3form (www.3-form.com). This is a beautiful product with a variety of finish options, customization as well as ready-to-go products. But the resin panels can range from $800 to $2,500 per 4′ x 8′ sheet. We always have in our back pocket some for budget translucency. We can’t offer the same patterns and textures as 3form, but there still can be translucency using LuxCore (www.atilaminates.com/luxcore/) or traditional acrylics with applied graphics.

Specialty lighting is a tough one to value engineer but with the help of a flexible electrician there can be solutions. LED strip lights can be a budget culprit, so keeping LED accents in a project may require a willingness to seek out suppliers that electricians may not have used before in order to save on material costs. We have learned that supplier research , vendor discussions as well as persistence pays off in this category of product.

And in some cases it can’t be substitutions, it has to be eliminations. Reducing the scope of a finish or detail can be the answer to budget woes, but only if the scope that is left is still significant enough to pull off the impact. If not, let it go.

6. Layering and Staging over Time:

In situations where the customer can’t be disappointed about the loss or reduction of their favorite design element, it may mean creating the opportunity for future adaptations to a design. For example, where a stone wall with a waterfall was planned but is no longer affordable, plumb for the water line, prepare the wall with appropriate substrates for moisture and then finish it off with paint. Schedule to review when the installation of the desired product could be added in the future.

And we believe the best budget measure you can take is to work with a firm like r.o.i. Design that is looking out for your return on your investment in design and construction. Ryan Bright our creative executive forwarded to all of us the following quote:

And we believe the best budget measure you can take is to work with a firm like r.o.i. Design that is looking out for your return on your investment in design and construction. Ryan Bright our creative executive forwarded to all of us the following quote:

“If you think it’s expensive to hire a professional to do the job, wait until you hire an amateur.”

Red Adair (1915-2004) An American oil well firefighter best known for completing over 1,000 jobs internationally.